Hybrid and Electric Aviation

Aviation has come a long way since the Wright Brothers’ first flight December 17, 1903 with the Wright Flyer. Only 73 years later, the British-French Concorde was conducting commercial services but civil aviation in the 20th century has seen few industry changing innovations except for the jet engine. Concorde’s last passenger flight took place on October 24th, 2003 signaling an end to commercialized supersonic transportation and with it the sonic boom and excessive fuel used by the aircraft. Evolving technology, restrictions, and increased safety regulations influence design characteristics that ultimately dictate how aircraft will look and perform in the modern transportation ecosystem.

Amphenol Innovation

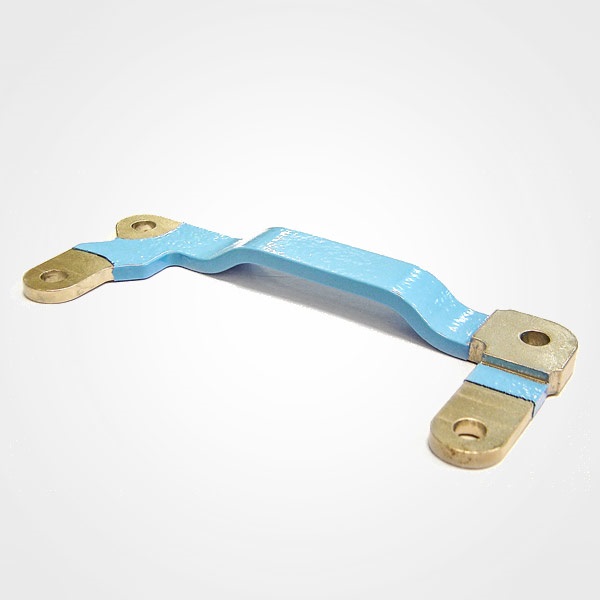

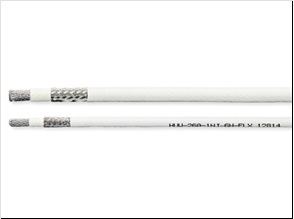

Electricity has become the source of innovation that will power disruptive change in the aerospace market enabled by light weight composites, hydrogen fuel cells, and a host of other technologies. Aircraft electrification provides an environmentally responsible solution by freeing the engineering and design constraints of aircraft design through the use of distributed electric propulsion (DEP), busbars vice drive shafts, and connectors able to deliver high voltage and current requirements at altitude. Amphenol has been and continues to be at the forefront of this aviation revolution by leading and pioneering projects to develop new products and materials enabling aircraft electrification. Our innovation through joint and collaborative efforts with academia and our customers supports the rebirth of a dynamic aerospace environment as supersonic, vertical, electric, and autonomous systems become real.

Click Here to view the entire Amphenol Hybrid and Electric Aviation product catalog that includes complementary products from many different Amphenol business units that each specialize in different electronic components manufacturing.

Amphenol Hybrid and Electric Aviation solutions

Join us as we enable this aerospace revolution and select from our wide range of products with unique capabilities and applications. Our products support the diverse range of aircraft in development with technologies to deliver the highest power density in a form factor with size and weight as main consideration.